OIL AND GAS INDUSTRIAL SYSTEM

-

Agroittica tanks in Pavia

-

Al-Fao oil tanks in Iraq

-

80000 cubic meter GPL tank

-

OCP refrigerated tanks in Morocco

-

Salam Gaz LPG sphere tank in Morocco

-

Industrial water tank in Civitavecchia

-

GPL sphere tanks in Eritrea

-

Cryogenic tanks in Iran

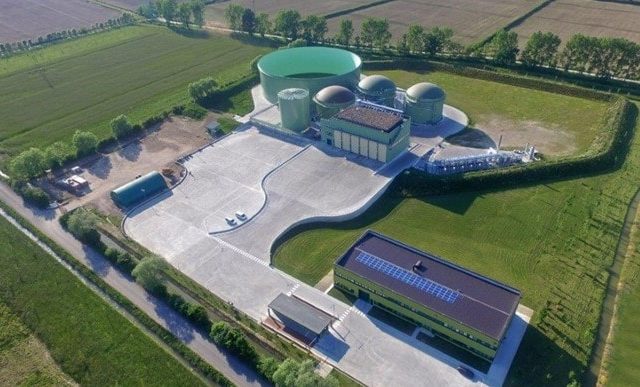

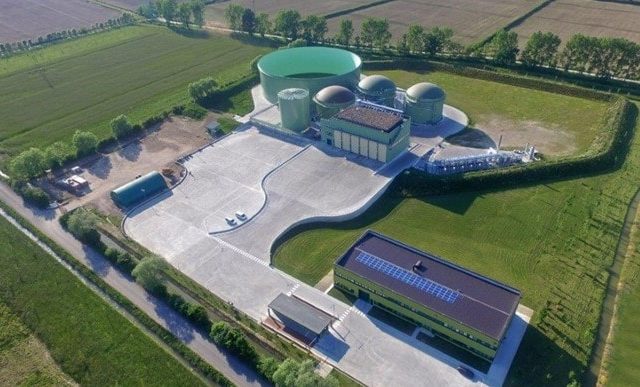

Agroittica tanks in Pavia

Agroittica tanks in Pavia

Foundations and ground consolidation works for a series of tanks of various sizes, part of a new plant aimed to recycle nutritional elements from wastes, in Vellezzo Bellini (PV).

The group of tanks belongs to an innovative system, which makes it possible to recycle organic waste, mostly coming from agricultural production residues, which are processed into liquid fertilizer, producing methane as a by-product.

In the plant five cylindrical steel tanks were built:

- One 50,000-cubic-metre tank for stocking the end product of the process, diameter 64 metres;

- Three 4,500-cubic-metre tanks used as digesters in the process, diameter 21 metres;

- One 4,000-cubic-metre tank for stocking ammonia salts, diameter 16 metres.

In order to reduce foundation settlements, the design of the foundations foreseen consolidation driven piles under each tank.

The piles used were truncated-cone precast r.c. type, 14 / 15 metres long, driven into soil without removing groun; as a total, 1,180 piles were driven.

The general design of the foundations is a perimeter annular reinforced concrete beam, inside which a coarse soil, of suitably diversified particle-size, is laid and compacted in layers; the perimeter beam, which was pre-compressed for the larger tank using post-tensioned strands, confines the compacted soil under the tank.

Services provided: Preliminary, final and execution design and construction management for special foundations and reinforced concrete and pre-compressed reinforced concrete structures.

Client: NEORURALE S.p.A.

Site: Municipality of Vellezzo Bellini, in the province of Pavia.

Years: from September 2013 to June 2015.

Cost of works: 1.05 million Euros

Al-Fao oil tanks in Iraq

Al-Fao oil tanks in Iraq

Special foundation and ground consolidation structures for eight new floating-ceiling 58,000-cubic-metre tanks, to be realized in the Al-Fao District industrial area, near Basra – Iraq.

These tanks are located in a large raw oil stocking area used to pump oil into tankers departing from the Persian Gulf.

In order to reduce foundation settlements, the design of the foundations envisaged consolidation columns under tanks, to be realized with the deep mixing method (DMM): the ground mechanically is mixed in-situ with an hydraulic binder, injected during perforation as cement mixture. The ground is broken and mixed by the combined action of mechanical tools and an high precision jet injection system, optimizing the mixing and increasing the final quality of the ground-binder mixture, especially in terms of strength and homogeneity of the consolidated columns section.

The foundations of the tanks were built on the ground thus consolidated, by laying layers of suitably compacted coarse soil, reinforced with a polyester geogrid: the base for the cylindrical wall of the tank is made up of a reinforced concrete annular beam.

Services provided: Preliminary, final and execution design for the soil consolidation and reinforced concrete structures.

Client: PARESA S.p.A. in a temporary joint venture with IBN MAJID State Company of Basra (Iraq).

Site: Al-Fao district industrial area, south of Basra (Iraq).

Years: 2014 and 2015.

Cost of works: over 20 million Euros.

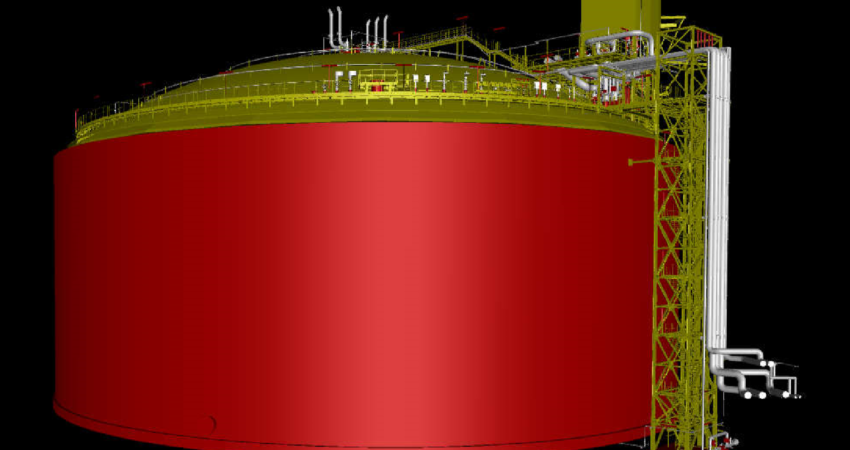

80000 cubic meter GPL tank

80000 cubic meter GPL tank

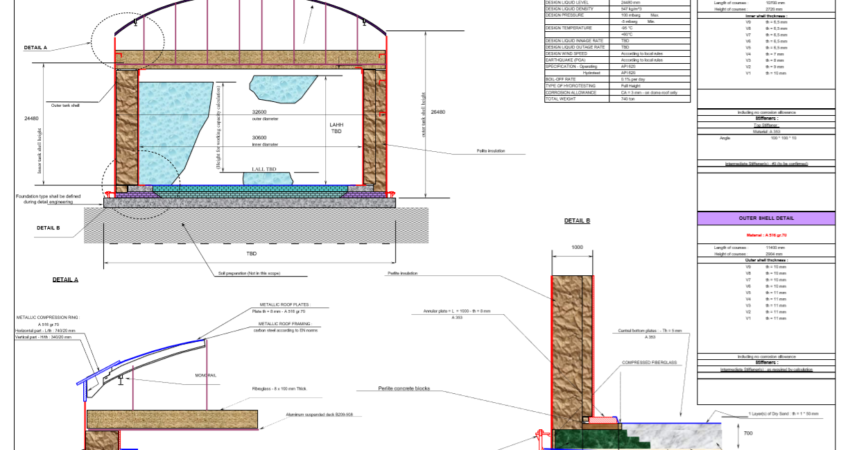

Civil works for the installation of a double-wall steel 80,000-cubic-meter tank for stocking liquefied propane.

The tank is made up of a cylindrical inner wall of diameter 65 metres and height 27.6 metres and a cylindrical outer wall of diameter 67 metres and height 29.2 metres, with a spherical cap cover approximately 10 metres high on top of the cylinder.

The foundations is made of over 480 reinforced concrete piles, cast-in-situ into steel tubes driven into soil, without removing any ground: the piles, 560 mm diam., were driven at depths between 8 and 15 metres, depending on substratum depth.

The piles support the platform supporting the tank, of diameter 72.2 metres and about 1 metre thick, made of r.c. about one metre above the ground. On this slab is also supported a cylindrical outer wall protecting the steel tank, also made of r.c., of outer diameter 71.6 metres, 26.9 metres high and 30 cm thick, realized using a sliding formwork.

The tank was completed with the related stair towers and a building hosting the service compressors.

Services provided: Preliminary design, execution design supervision and technical assistance during the civil works.

Client: PARESA S.p.A.

Years: 2017-2019.

OCP refrigerated tanks in Morocco

OCP refrigerated tanks in Morocco

Foundations and reinforced concrete civil works for eight double-wall 4,300-cubic-metre tanks for stocking liquefied ammonia in the OCP plant of Jorf Lasfar (Morocco).

These tanks were built in the main plant for processing phosphates mined in southern Morocco.

The tanks are insulated, double-wall steel structures; they are made up of a cylindrical inner wall of diameter 17 metres and height 19 metres and a cylindrical outer wall of diameter 19.4 metres and height 20.7 metres, with a spherical cap cover 2.6 metres high on top of the cylindrical wall.

The foundations are made of a reinforced concrete slab of diameter 20.6 metres and thickness 50 cm, supported by a lean concrete base of variable thickness, depending on the actual depth of the marly substratum. The platform supports 24 radial walls 30 cm thick, supporting a second reinforced concrete slab of diameter 20.1 metres and 50 cm thick, supporting the tank, at a level higher than the ground.

The foundations for the plants connected with the tanks and for four control buildings were also designed.

Services provided: Constructive project and technical assistance to the implementation of the civil works and the foundations.

Client: PARESA S.p.A.

Site: OCP plant at Jorf Lasfar (Morocco).

Years: 2012-2013.

Cost of works: about 27 million Euros

Salam Gaz LPG sphere tank in Morocco

Salam Gaz LPG sphere tank in Morocco

Foundation and civil works for a 6,000-cubic-metre steel sphere for storing liquid butane gas in the Salam-Gaz plant of Fes/Meknes (Morocco).

The steel sphere for stocking pressure-liquefied gas has a diameter of 22.6m, with a top height of 25 metres from ground: twelve steel columns with round sections and a diameter of about 1 metre support the sphere.

The foundations is an underground reinforced concrete perimeter annular beam with a reverse-T section, 2.7 metres high and 6.3 metres wide.

The foundations for the plants connected with the tanks and for the walls around tank were also designed.

Services provided: Execution design and technical assistance to the implementation of civil works and foundations.

Client: PARESA S.p.A.

Site: Salam-Gaz plant of Fes/Meknes (Morocco).

Years: 2015-2016.

Cost of works: about 4 million Euros

Industrial water tank in Civitavecchia

Industrial water tank in Civitavecchia

Foundations and civil works for a 2,000-cubic-metre tank for stocking industrial water in the ENEL thermoelectric plant near Civitavecchia (Rome).

The cylindrical steel tank has a diameter of approximately 14 metres and is 14.6 metres high.

The foundations are made of a reinforced concrete perimeter annular beam with a reverse-T section, with an average diameter of 13.9 metres, 1.3 metres high and 1.5 metres wide.

Inside the annular beam there is a coarse soil with suitably diversified particle-size is placed in compacted layers.

In addition to this, the civil works related to the tank systems were designed.

Services provided: Execution design and technical assistance to the implementation of civil works and foundations.

Client: PARESA S.p.A.

Site: ENEL thermoelectric plant of Torrevaldaliga Nord, near Civitavecchia (Rome).

Years: 2012-2013.

Cost of works: about 740,000 Euros

GPL sphere tanks in Eritrea

GPL sphere tanks in Eritrea

Reinforced concrete foundations and civil works for two 2,000-cubic-metre steel spheres for stocking LPG and for a 1,000-cubic-metre tank for firefighting water in the Massawa warehouse (Eritrea).

The steel spheres for stocking liquefied gas have a diameter of 15.6 metres, with a top height of about 18 metres from the ground; ten steel columns of circular section and diameter of about 0.7 metres support the sphere.

The foundations of each sphere is made of an underground annular beam with a reversed-T section, 1.7 metres high and 5.7 metres wide.

The steel water-tank has a cylindrical wall of inner diameter 12.5 metres and height 8.5 metres.

The water-tank foundations are made up of a perimeter annular beam of 1.1 m high, made of reinforced concrete, inside of which a coarse soil, with a suitably diversified particle-size, is placed in compacted layers.

In addition to this, the foundations for the tank plants and a reinforced concrete road leading to the warehouse were designed.

Services provided: Execution design and technical assistance for civil works and foundations.

Client: PARESA S.p.A.

Site: Ministry of Energy warehouse in Massawa (Eritrea).

Years: 2011-2012.

Cryogenic tanks in Iran

Cryogenic tanks in Iran

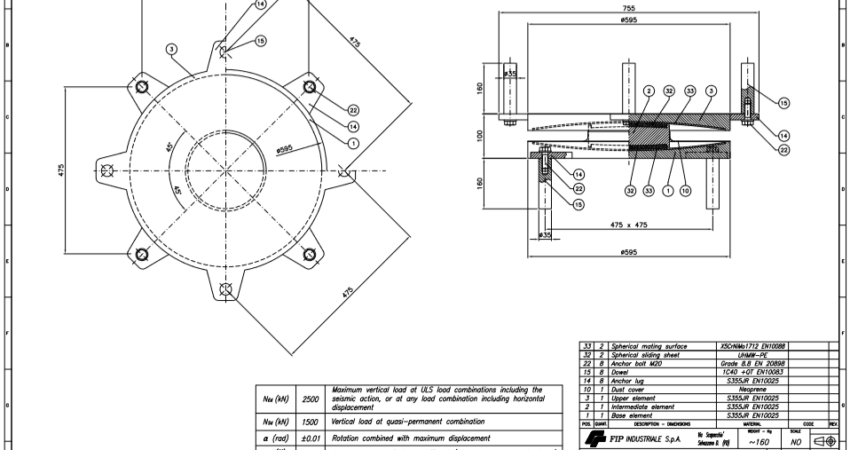

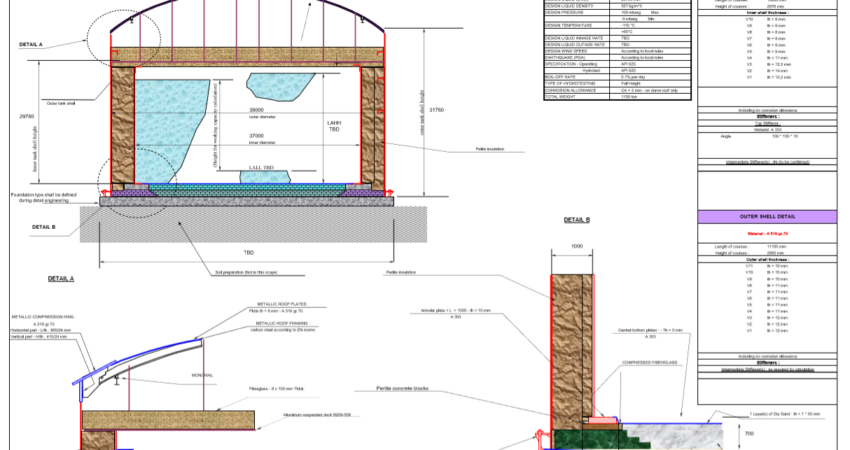

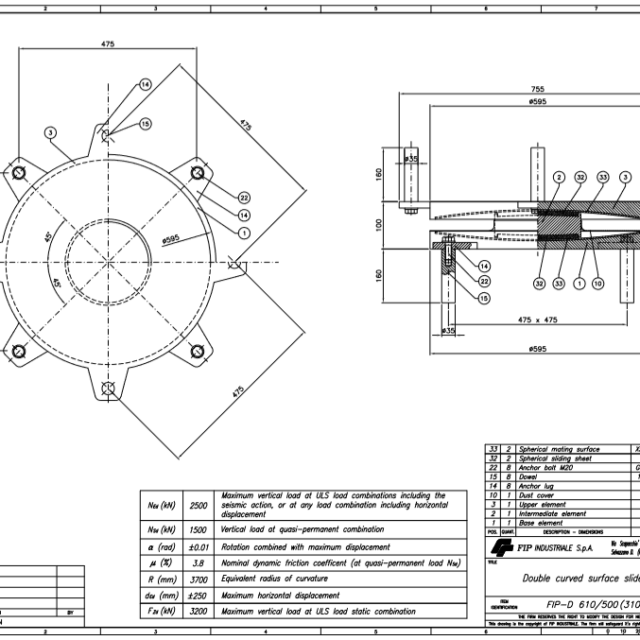

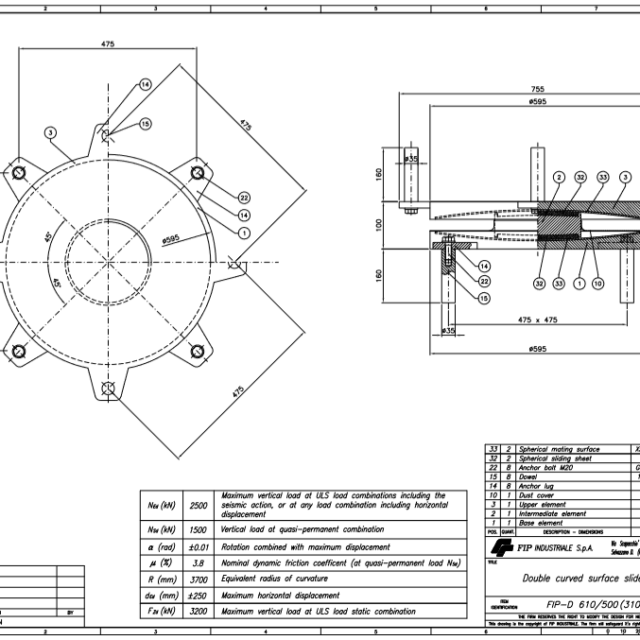

Foundations with seismic insulators to build two double-wall steel tanks, a 32,000-cubic-metre tank for stocking ethylene and an 18,000-cubic-metre tank for stocking ethane in the OLEFIN PLANT of “South Pars Oil and Gas Field” (IRAN).

These are insulated double-wall steel tanks; the tank for ethylene storage is made of a cylindrical inner wall of diameter 37 metres and height 29.8 metres and a cylindrical outer wall of diameter 39 metres and height 31.8 metres. The tank for ethane storage is made of a cylindrical inner wall of diameter 32.6 metres and height 24.5 metres and a cylindrical outer wall of diameter 32.6 metres and height 26.5 metres.

The peculiarity of this project is the need for seismic insulation of the tanks, due to the particularly high seismic risk of the site.

For this purpose, the reinforced concrete circular platforms 80 cm thick supporting the tanks are designed to be supported on damped pendulum seismic insulators made of two steel spherical cap surfaces separated by a sliding piece, with a friction suitable to damp the oscillatory energy. Totally, 190 insulators are foreseen under the ethylene tank and 113 are foreseen under the ethane tank.

Each insulator is supported by a column, and the columns are bound to underground circular platforms 120 cm thick, supported at a depth of about 2.5 m; the columns and the lower platforms are foreseen in reinforced concrete.

Service provided: Preliminary design for bid.

Client: PARESA S.p.A.

Site: OLEFIN PLANT in “South Pars Oil and Gas Field” (IRAN).

Year: 2018.

Cost of works: about 22 million Euros